Do you operate your Kanga daily? To keep your machine running at optimum performance, you want to make sure to carry out a few easy and quick Kanga Loader service checks on your compact loader. Read on for a summary of the most important points.

Check your grease nipples along the pivot points of the main & tilt arm. Grease should be visible around the grease pins. Generally, we recommend greasing them every 10 working hours.

Make sure your collector pre-cleaner is not overflowing (see max. indicator). The pre-cleaner is located to the left of the main arm. To open it, unscrew the top cap, remove the pre cleaner container, and dispose of the dust.

Make sure your air filter is clean. Open the air filter cap, remove your air filter, and tap the filter against a hard surface to knock the dust out – If your filter is excessively dirty, you might want to consider replacing it. Generally, we recommend replacing it every 100 hours.

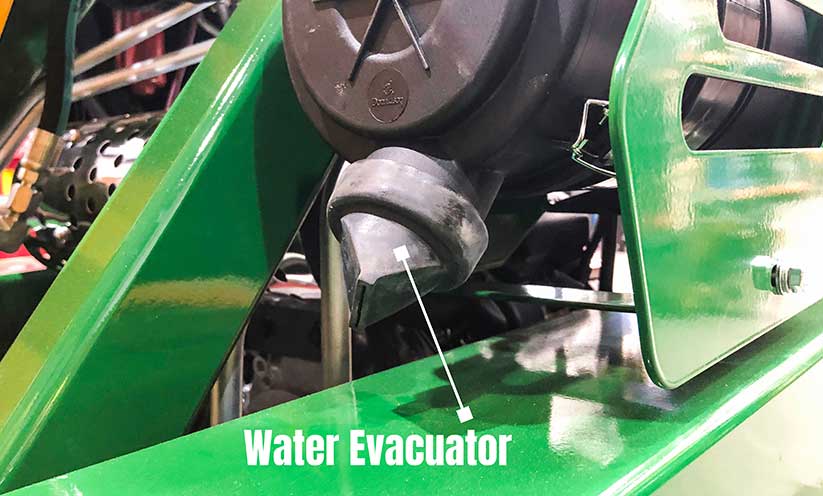

The water evacuator is located below the air filter and always needs to be intact to ensure excess water is removed away from the engine. Please ensure that your water evacuator is secure and not damaged.

Check the level of your oil and refill, if necessary. Remove the dip stick, wipe clean, reinsert, and then check the level – The oil level should show between the two marks on the dipstick.

Before checking the hydraulic oil, you will need to get your machine to operating temperature. Generally, one can tell when the oil cooling fan has engaged.

Note: The outside temperature will affect how quickly a machine heats up). Once at operating temperature, make sure to check the hydraulic oil by removing the dipstick. Levels should show between the two marks. Then, refill if necessary.

Visually inspect hoses and potential leaking points of your machine along the arm as well as on your compact loader attachments.

Finally, check your tire pressure (the PSI depends on the type of tire – Please refer to your operator’s manual). Also, ensure that wheel nuts are tightened. We recommend a wheel nut tension of 100 Nm for our 6-8 Series machines.

Please note: Images show a 6 series gas compact loader – The position of dipsticks will differ on a diesel loader. Please refer to your operator’s manual for further specifications and Kanga Loader Service checks, or give us a call on 833 305 2642 (833 30 KANGA). You can also contact us via our contact page.

Leave a Reply